Shandong Yabin Medical Technology Co., Ltd.

SHANDONG YABIN MEDICAL TECHNNOLOGY CO. Ltd.

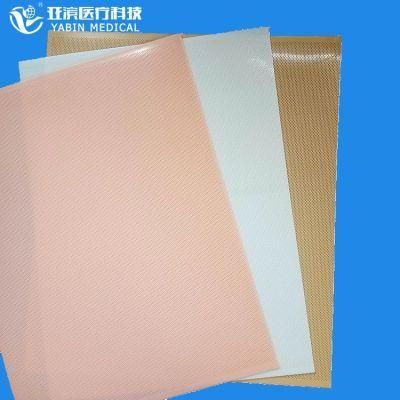

Shandong Yabin Medical Technology Co., Ltd. is a high-tech enterprise located in Qilu Chemical Industrial Park, Zibo city, Shandong Province. Relaying on the patented technology, design and produce the low temperature thermoplastic sheets, which used in the field of plastic surgery, orthopedics, rhinoplasty, oncology radiation therapy. The company has a professional design team, has a variety of independent self-designed advanced equipment, has innovative marketing team. The products are not only meet the domestic market, but also wins a high reputation in international market, such as United States, Canada, UK, Europe, Australia, New Zealand, India, Africa and others.

Yabin medical produced classify I products with CE FDA ISO13485 certification.

What is the difference between activating splinting materials with a dry heater VS a water bath?

The activation of thermoplastic sheet materials by means of a water bath at 65° C-75° C / 149° F-167 ° F goes faster than a dry heater due to the much higher heat transfer rate of water compared to air. On the other hand, those splints will cool down faster when molding due to the remaining water layer which remains present on the surface. The evaporation of this thin water layer subtracts the heat on a much higher level compared with dry heating. Another aspect which is influenced when using water is the stickiness: The small water layer also acts as a non-sticking layer; It will prevent the splint from sticking more than dry heating would.

The activation by means of a dry heater is more hygienic due to the lack of water. As there is no water layer involved on the splint, the crystallization time is longer, which gives the therapist or splint fabricator more time to fabricate the splint on the patient. The splint will also have a more sticky feeling as there is no water layer present. This additional stickiness can help the fabrication process by means of the so-called "third hand", allowing the material to stay in place while the therapist positions the extremity and forms the design.

Why choose us?

Strong Plasticity

Easily shaped by patients′ affected positions. Will not rebound after cooling

100% of the memory function

If it can′t fit to the patients well, put it back into the hot water and reshaped. It will be quickly recovered to original and can reuse about 6-8 times and realize cost saving.

Good breath ability.

The holes on the materials surface can keep good transmittance, avoid necrosis of the affected infection.

Practical

It has the features of toxic-free tasteless, easy cleaning in cold water after shaped, can wear it during bath, can be penetrated by X-ray, no need to take off when do the X-ray

Eco-friendly

After 1 year, it can be degraded by itself in natural conditions, no pollution to environment.

Good tensile

It has good tensile, can stretch in all direction with 1-1.5 time

Shandong Yabin Medical Technology Co., Ltd. is a high-tech enterprise located in Qilu Chemical Industrial Park, Zibo city, Shandong Province. Relaying on the patented technology, design and produce the low temperature thermoplastic sheets, which used in the field of plastic surgery, orthopedics, rhinoplasty, oncology radiation therapy. The company has a professional design team, has a variety of independent self-designed advanced equipment, has innovative marketing team. The products are not only meet the domestic market, but also wins a high reputation in international market, such as United States, Canada, UK, Europe, Australia, New Zealand, India, Africa and others.

Yabin medical produced classify I products with CE FDA ISO13485 certification.

What is the difference between activating splinting materials with a dry heater VS a water bath?

The activation of thermoplastic sheet materials by means of a water bath at 65° C-75° C / 149° F-167 ° F goes faster than a dry heater due to the much higher heat transfer rate of water compared to air. On the other hand, those splints will cool down faster when molding due to the remaining water layer which remains present on the surface. The evaporation of this thin water layer subtracts the heat on a much higher level compared with dry heating. Another aspect which is influenced when using water is the stickiness: The small water layer also acts as a non-sticking layer; It will prevent the splint from sticking more than dry heating would.

The activation by means of a dry heater is more hygienic due to the lack of water. As there is no water layer involved on the splint, the crystallization time is longer, which gives the therapist or splint fabricator more time to fabricate the splint on the patient. The splint will also have a more sticky feeling as there is no water layer present. This additional stickiness can help the fabrication process by means of the so-called "third hand", allowing the material to stay in place while the therapist positions the extremity and forms the design.

Why choose us?

Strong Plasticity

Easily shaped by patients′ affected positions. Will not rebound after cooling

100% of the memory function

If it can′t fit to the patients well, put it back into the hot water and reshaped. It will be quickly recovered to original and can reuse about 6-8 times and realize cost saving.

Good breath ability.

The holes on the materials surface can keep good transmittance, avoid necrosis of the affected infection.

Practical

It has the features of toxic-free tasteless, easy cleaning in cold water after shaped, can wear it during bath, can be penetrated by X-ray, no need to take off when do the X-ray

Eco-friendly

After 1 year, it can be degraded by itself in natural conditions, no pollution to environment.

Good tensile

It has good tensile, can stretch in all direction with 1-1.5 time

Product List